Darwin FTW

By the time I built my first drum pedal over a decade ago during vocational training to become a mechanical engineer, I had no clue what will develop out of it.

It all began a couple years ago, when I first played with the idea of buying a high-quality drum pedal. For a lefthanded person like me the choice is unfortunately very limited.

When I looked deeper into the subject, I came across many things that bugged me about the available products – from the general construction to adjustment possibilities and inconsiderable things like the tension spring and its geometry.

The aim was to produce a pedal with possibilities for everyone to find their setup. It should run well balanced in its basic setup, but if anyone wants to experiment a little bit they should have the opportunity to do so. You should be able to adjust any parameter and play with different combinations anywhere the drum key fits.

The pedal has developed in small steps over the years. Compromises were unwanted - problems that couldn’t be solved immediately were left aside until I got the sparking idea.

During the past months I've worked on a few new features for the Darwin pedal series. Thanks to all the support and the great community around ACD it was possible to figure out the tiny little details that makes the setup, traveling or experimenting with the Darwins even easier in everyday life. All this background knowledge has resulted in the new Darwin FTW series!

Symmetric Design

The Darwin FTW series always offers a true left and a true right pedal layout! Both legs, especially the feet are shaped different and this setting provides the best symmetrical feeling and freedom for both, regardless of your preferred setup!

Footboard Types

Shortboard

The classic geometry. The foot board is expanded by a fixed heel part. The base plate is identical to the long board version.

Longboard

Its length corresponds to the short board plus heel part. Due to the altered lever it runs light-footed and offers the opportunity to experiment.

Short and long board sharing the same base plate, which makes it easy to swap them.

The heel block is supported by solid ball bearings guarantee a stable and smooth performance.

Drive

The Darwin is developed to offer a wide range customizable features, in order to fit a drummers very personal needs. Besides general adjustments, the FTW version can be switched between a StrapDrive and a DirectDrive setup within minutes. (Video)

Depending on the drive system and the related setup used, the characteristics can reach from solid & heavy to quick & dirty and every combination in-between.

All of that is based on the split drive cam that allows to adjust several essentiell geometry parameters in combination with an independently adjustable connection on the

footboard.

So what is the difference between StrapDrive and DirectDrive?

It's hard to put into words. Generally spoken the average strap/chain drive releases the brought-in energy more linier, while the DirectDrive likes to releases the energy more abruptly. Moving to

an excentric setup, the StrapDrive starts lightweight and builds up more momentum during the movement, while the DirectDrive usually tends to act the other way around.

With that being said, I'd like to mention that every pedal can feel and react differently, regardless of its drive system, due to the huge influence of other parameters. The Darwin

offers a very wide range to adjust and combine these specific characteristics.

Not sure what to pick?: Based on my long-term experience talking to customers, my recommendation for the most versatile and efficient Darwin setup is the strap drive

configuration. It has proven to be right versions for most drummers, especially, if you are looking for a very responsive, powerful and fast (yes, trust me!) setup that easily follows the

guidance of your foot (and not the other way around). If you are used to the non-linear feeling of a direct drive setup, or if you play a specific genre that requires extreme tempos (and

nothing else). If you are still uncertain, I'm always more than happy to guide you. Please contact me anytime.

Also: YOUTUBE

Mixing cam parameters with general adjustments, such as beater- & footboard angle, beater weight, spring tension,... it can be very hard to tell which drive system is currently

installed on the Darwins. Running through various setups, I experienced, that a DirectDrive setup can come very close to a StrapDrive, and the other way around.

Strap Drive

The strap drive is the perfect alternative to conventional chain driven pedals. Due to modern materials, it offers more smoothness and less gyrating mass in comparison to a chain.

The belt was developed in collaboration with a German strap producer. It’s made of a thin mixture of nylon and kevlar and features a layer of neoprene on its support surface. The strap is smooth, high-tensile and absolutely wear-free and can be fixed at different positions on the foot board. Thus the height of the foot board can be optimized independent of the whole drive.

The geometry of the cam offers a defined tearing edge, which, if necessary, can be intensified or dampened by twisting the cam. By emphasizing the tearing edge, the beater is additionally speed up on the last part of its rotary motion.

Due to the belt drive you can’t just twist the cam, but you can also adjust it continuously from round to an eccentric pulley. In combination, both parameters offer many possibilities to alter the running characteristics to your personal preferences.

Direct Drive

DirectDrive has developed a big fanbase and is a popular alternative to modern chain- or strap driven systems, with reason!

Set up as DirectDrive pedal, the Darwin uses the split cam to adjust the top leverage and cam-rotation. The former footboard height adjustment turns into a second way to change the

drive's leverage with its very own characteristics. The length-adjustable DirectDrive link allows to set the preferred footboard hight independently from other parameters.

Experimenting with these adjustments is not only lots of fun, it also offers a world of possibilities.

Hoop Clamp & Main Spring

The hoop clamp was planned as an individual unit, to make it possible to adjust it lengthwise and crosswise. On the one hand, to adjust the distance to the skin, so that the beater meets the skin at its highest point and doesn’t overwind. On the other hand, to center the single pedal beater or the middle of the double pedal beaters on the skin. The hoop is clamped between gentle, slip-proof rubber supports.

The geometry of the spring is underestimated although it is the secret centrepiece of a pedal.

I experimented a lot with the spring’s geometry during the development of the prototypes.

Not only with different lengths, strengths and materials, but also with angles and distances.

The result is a performance that is only possible with a high basic stress on popular pedals.

The geometry was optimized, so the pedal already runs very smooth with a low basic spring tension. The spring itself is supported by ball bearings on both ends and easily adjustable by hand. It’s so easy, you can even find a setup while playing.

Reference Marks

Various reference marks on all moving parts make it easy to find and replicate setups.

Also its good fun to share and discuss them within the Darwin community.

DriveShaft

The drive shaft is the well known Ultimate DriveShaft, which is already known as an upgrade solution. It’s a construction from aluminium, ball bearing supported all around, slightly prestressed and absolutely free of play. Stainless steel inserts all around reinforce the threads.

Beater

The pedal is delivered by default with the Dynamic Beater, which is a construction from aluminium with an optimized geometry and interchangeable rear weights and surfaces.

Transport

Like a snare drum, a pedal is likely to be an indispensable companion on the road and on gigs abroad.

From the very beginning, the Darwin featured a way to disconnect the main pillar from the pedal. The new adapter plate, combined with a lightweight design (Sinlge 2kg (4.4lb) | Double 4.5kg

(9.9lb)) makes the Darwin FTW more than just travel friendly.

The new backpack comes with every single-, double- and middle pedal. Depending on how much extra space is needed, the pedal fits either completely "folded" along with personal essential, or just "traditionally" disassembled in this bag.

The backpack also offers enough space for sticks and cables along with a separate 13" laptop section. The inside fitting is completely customizable to fit your personal needs.

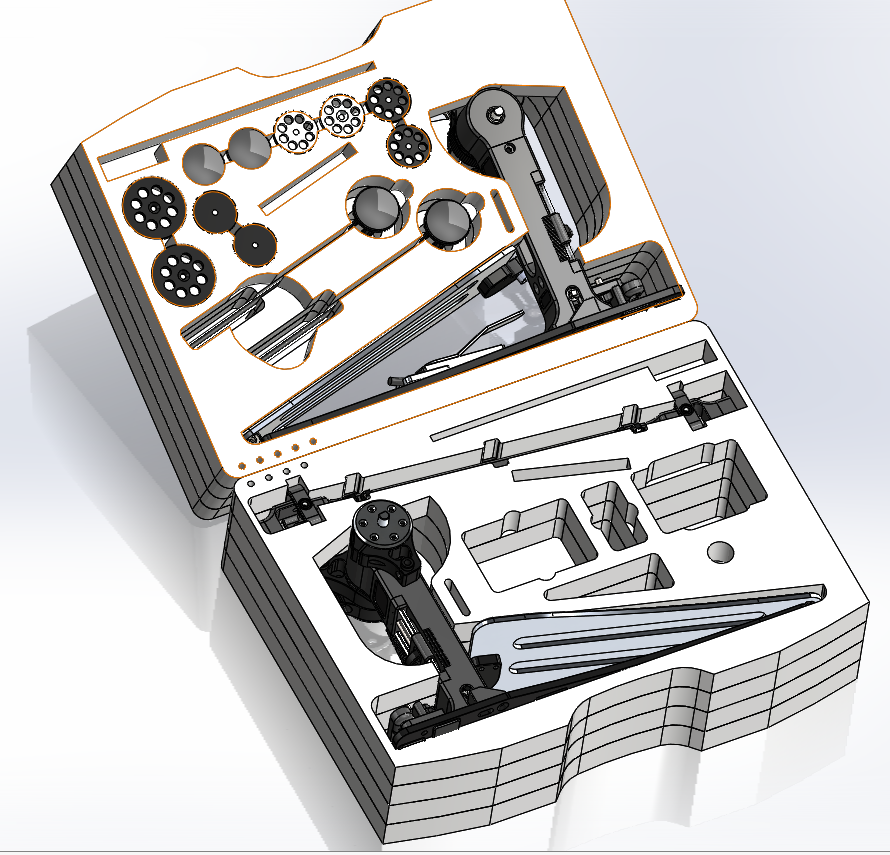

For those who need more protection during touring, the Darwin can now also be delivered with a hardcase. Customized foam inserts either fit a single, double or middle pedal along with all additional parts. I'm currently trying to implement the transport options in the online shop, until then I clarify the preferred option with the purchase confirmation.

Versions

The pedal is available as single, double or middle pedal – right-handed as well as left-handed. Both with all different foot boards as well as belt or direct drive.

The double pedal can quickly be converted to two single pedals. Just dissemble the drive shaft and put the beater into the second pedal.

Like all my products the pedals are produced in small batch series and assembled by hand.

Click here to get to the online shop.

Any questions? - Feel free to contact me anytime!